Introduction

A1.

Penta-Ocean - Concentric

Joint Venture (POCJV) is contracted to carry out the Mainlaying in Tseung Kwan O under Contract No. 13/WSD/16

(hereinafter known as “the Project”).

A2.

In accordance

with the Environmental Monitoring and Audit (EM&A) Manual for the Project, EM&A

works should be carried out by Environmental Team (ET), Acuity Sustainability

Consulting Limited (ASCL), during the construction phase of the Project.

A3.

This is the 56th

Monthly EM&A Report,

prepared by ASCL,

for the Project summarizing the monitoring results and audit findings of the

EM&A programme at and around Tseung Kwan O (TKO) during the reporting

period from 1 March to 31 March 2023.

A4.

The EM&A

programme for this contract has covered environmental monitoring on

construction noise level at selected NSRs and Contractor’s environmental

performance auditing in the aspects of construction dust, construction noise,

water quality, waste management, landscape and visual and ecology.

Summary of Main Works Undertaken

& Key Mitigation Measures Implemented

A5.

Key works carried out in this reporting period for

the Project included the followings:

|

Location

|

Construction activities

carried in the reporting month

|

|

Wan Po Road and TKO Area 137

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

|

|

TKO Promenade (Stage 1 Landfill) & Po

Yap Road Roundabout

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

·

Trenchless

Method (sleeve pipe)

|

|

HK Velodrome

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

·

Trenchless

Method (sleeve pipe)

|

|

Po Lam Road South / Ling Hong Road

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

|

|

Tsui Lam Road / Abandoned Road

|

·

Open

trench method

·

Pile cap

construction

|

A6.

The major

environmental impacts brought by the above construction works include:

·

Construction

dust and noise generation from mainlaying of pipes, and excavation;

·

Waste

generation from the construction activities; and

·

Impact on water

quality from construction activities

A7.

The key

environmental mitigation measures implemented for the Project in this reporting

period associated with the above

construction works include:

·

Reduction of

construction dust generation from mainlaying of pipes, and excavation;

·

Reduction of

noise from equipment and machinery on-site;

·

Sorting and

storage of general refuse and construction waste; and

·

Treatment of

wastewater through water treatment facilities before discharge

Summary of Exceedance & Investigation

& Follow-up

A8.

Noise

monitoring was scheduled in the reporting month for NSR4 Creative Secondary

School on 1, 7, 13, 24 and 30 March 2023 as construction works were conducted

within 300m to the noise sensitive receiver. No Action or Limit Level

exceedance was recorded during the reporting period.

A9.

Landfill gas

monitoring was carried out by the Registered Safety Officer of the Contractor

at the excavation locations and within the consultation zones for 564 times. All the measured results were

presented in Appendix J and were within the Action and Limit Levels.

Complaint Handling and

Prosecution

A10. No environmental complaint,

notifications of summons and prosecution was received in the reporting month.

Reporting Change

A11.

There were

no changes reported that may affect the on-going EM&A programme.

Summary of Upcoming Key Issues and Key

Mitigation Measures

A12.

Key works in the next reporting month for the

Project will include the followings:

|

Location

|

Construction activities to be

carried out in next reporting month

|

|

Wan Po Road and TKO Area 137

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

|

|

TKO Promenade (Stage 1 Landfill) & Po

Yap Road Roundabout

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

·

Trenchless

Method (sleeve pipe)

|

|

HK Velodrome

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

·

Trenchless

Method (sleeve pipe)

|

|

Po Lam Road South / Ling Hong Road

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

|

|

Tsui Lam Road / Abandoned Road

|

·

Open

trench method

|

A13. The major environmental impacts

brought by the above construction works will include:

·

Construction

dust and noise generation of mainlaying of pipes, and excavation works;

·

Waste

generation from construction activities; and

·

Impact on

water quality from construction activities.

A14. The key environmental mitigation

measures for the Project in the coming reporting period associated with the

above construction works will include:

·

Reduction of

construction dust generation of mainlaying of pipes, and excavation works by regular

water spraying and covering of dusty materials with screenings;

·

Reduction of

noise from equipment and machinery on-site;

·

Sorting and

storage of general refuse and construction waste; and

·

Treatment of

wastewater through water treatment facilities before discharge.

1.1

Background

The proposed Desalination Plant

at Tseung Kwan O (DPTKO) will produce potable water with an initial capacity of

135 million liters per day (MLD), expandable to an ultimate capacity of 270 MLD

in the future to provide a secure and alternative freshwater resource complying

with the World Health Organization (WHO) standards. The plant will adopt the

Seawater Reverse Osmosis (SWRO) technology, which dominates the market due to

its reliability and progressive reduction in cost as the technology advances.

Pursuant to the Environmental Impact

Assessment Ordinance (EIAO), the Director of Environmental Protection granted

the Variation of Environmental Permit (No. EP-503/2015/A) to Water Supplies

Department (WSD) for the Project on 26 January 2018.

The scope of the Contract may be considered

in brief, to consist of the laying of about 10 km long 1200 mm diameter freshwater

mains and the associated works along the alignment of the Project as shown with

the overall view in Appendix

B.

1.2

The

Reporting Scope

This

is the 56th Monthly EM&A Report for the Project which summarizes

the key findings of the EM&A programme during the reporting period from 1 March to 31 March 2023.

1.3

Project

Organization

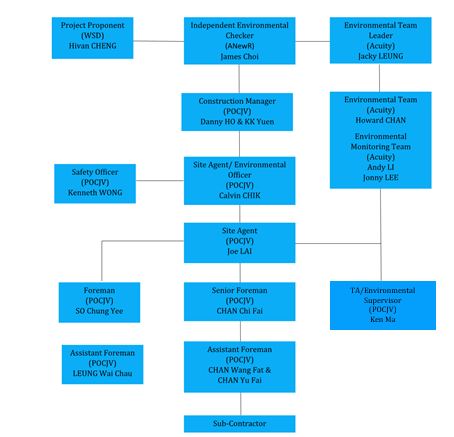

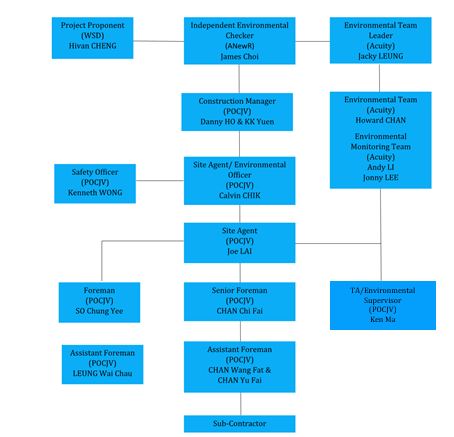

The

Project Organization structure for Construction Phase is presented in Figure

1.1.

Figure 1.1 Project Organization Chart

Contact

details of the key personnel are presented in Table 1.1 below:

Table 1.1 Contact details of the

key personnel

|

Party

|

Position

|

Name

|

Telephone

no.

|

|

Penta-Ocean - Concentric Joint Venture

|

Environmental Officer

|

Calvin Chik

|

9863 5630

|

|

Acuity Sustainability Consulting Limited

|

Environmental Team Leader

|

Jacky Leung

|

2698 6833

|

|

ANewR Consulting Limited

|

Independent Environmental Checker

|

James Choi

|

2618 2831

|

1.4

Summary

of Construction Works

Details

of the major construction works undertaken in this reporting period are shown

in Table 1.2 and the construction works locations are shown in Appendix

B. The construction programme is presented in Appendix A.

Table 1.2 Summary of the Construction Works Undertaken during the

Reporting Month

|

Location

|

Construction activities carried

out in the reporting month

|

|

Wan Po Road and TKO Area 137

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

|

|

TKO Promenade (Stage 1 Landfill) & Po

Yap Road Roundabout

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

·

Trenchless

Method (sleeve pipe)

|

|

HK Velodrome

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

·

Trenchless

Method (sleeve pipe)

|

|

Po Lam Road South / Ling Hong Road

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

|

|

Tsui Lam Road / Abandoned Road

|

·

Open

trench method

·

Pile cap

construction

|

A summary of the valid permits, licences,

and or notifications on environmental protection for this Project is presented

in Table 1.3.

Table 1.3 Summary of the Status of Environmental Licence, Notification

and Permit

|

Reference No.

|

Valid Period

|

Status

|

Remark

|

|

From

|

To

|

|

Variation of

Environmental Permit

|

|

EP no.: EP-503/2015/A

|

--

|

--

|

Valid

|

N/A

|

|

Notification

of Construction Works under the Air Pollution Control (Construction Dust)

Regulation

|

|

423775

|

--

|

--

|

Valid

|

N/A

|

|

Chemical

Waste Producer Registration

|

|

5213-839-P3287-01

|

--

|

--

|

Valid

|

N/A

|

|

Billing

Account for Disposal of Construction Waste

|

|

A/C no.: 7029491

|

--

|

--

|

Valid

|

N/A

|

|

Water

Discharge Licence

|

|

WT00032336-2018

|

10 Dec 2018

|

31 Dec 2023

|

Valid

|

N/A

|

|

Construction

Noise Permit (CNP)

|

|

GW-RE0109-23

|

8 Feb 2023

|

31 Mar 2023

|

Expired

|

Po Shun Road near junction of

Wan Po Road

|

|

GW-RE0091-23

|

6 Feb 2023

|

29 Apr 2023

|

Valid

|

Construction site near

junction of Wan Po Road and Pung Loi Road

|

The status for all environmental aspects is

presented Table 1.4.

Table 1.4 Summary of Status for Key Environmental

Aspects under the EM&A Manual

Other than the EM&A works by ET,

regular environmental management meetings were conducted in order to enhance

environmental awareness and closely monitor the environmental performance of

the contractors.

The

EM&A programme has been implemented in accordance with the recommendations

presented in the approved EIA Report and the EM&A Manual. A summary of

implementation status of the environmental mitigation measures for the

construction phase of the Project during the reporting period is provided in Appendix

C.

2

2.1

Monitoring

Requirements

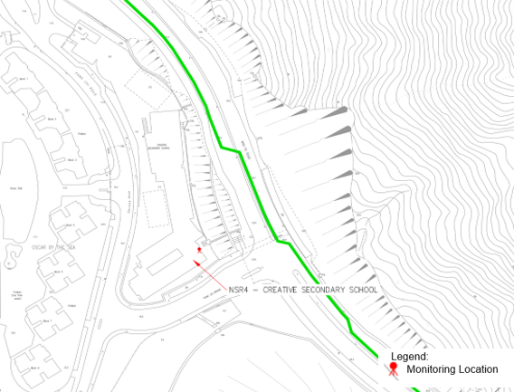

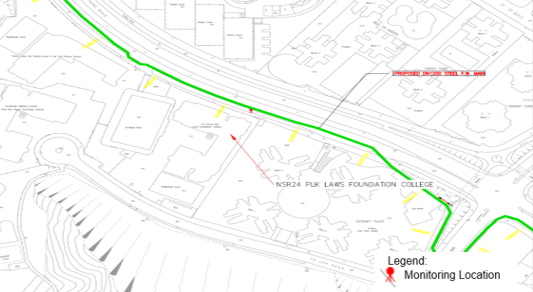

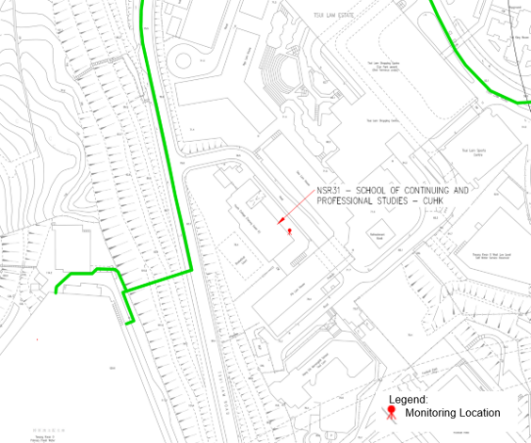

To ensure no adverse noise impact, noise

monitoring is recommended to be carried out within 300m radius from the nearby

noise sensitive receivers (NSRs), during construction phase. The NSRs selected as monitoring

station are (i) NSR4 – Creative Secondary School, (ii) NSR24 – PLK Laws Foundation

College, and (iii) NSR31 – School of Continuing and Professional Studies – CUHK

respectively.

Referring

to EM&A Manual Section 4.1.2, the impact noise monitoring should be carried

out at all the designated monitoring stations when there are project-related

construction activities undertaken within a radius of 300m from the monitoring

stations.

Impact

monitoring for noise impact was conducted in the reporting month for NSR4 –

Creative Secondary School on 1, 7, 13, 24 and 30 March 2023 as construction

works were conducted within 300m to the noise sensitive receiver. Detailed

monitoring results can be found in Appendix G.

2.2

Noise

Monitoring Parameters, Time, Frequency

Impact noise monitoring was conducted

weekly in the reporting period between 0700-1900 on normal weekdays. Construction

works will follow the requirements as stipulated in the valid CNPs if works

have to be conducted in

the restricted hours.

Construction noise level was measured in

terms of the A-weighted equivalent continuous sound pressure level (LAeq).

Leq 30min was used as the monitoring parameter for the time period

between 0700 and 1900 on normal weekdays. Table 2.1 summarizes the monitoring parameters, frequency,

and duration of the impact noise monitoring. The monitoring schedule is

provided in Appendix D.

Table 2.1 Noise Monitoring Parameters, Time, Frequency and Duration

|

Time

|

Frequency

|

Duration

|

Parameters

|

|

Daytime:

0700-1900

|

Once per week

|

Continuously in

Leq 5min/Leq 30min (average

of 6 consecutive Leq 5min)

|

Leq, L10 & L90

|

2.3

Noise

Monitoring Locations

The monitoring locations should normally be

made at a point 1m from the exterior of the NSRs building façade and be at a

position 1.2m above the ground. A correction of +3dB(A) should be made to the

free-field measurements.

According to the environmental findings

detailed in the EIA report and Baseline Monitoring Report, the designated

locations for the construction noise monitoring are listed in Table 2.2

below.

Table 2.2 Noise

Monitoring Location

|

NSR ID

|

Noise Sensitive Receivers

|

Monitoring Location

|

Position

|

|

NSR 4

|

Creative Secondary School

|

Roof Floor

|

1 m from facade

|

|

NSR 24

|

PLK Laws Foundation College

|

Pedestrian Road on Ground Floor

|

Free-field

|

|

NSR 31

|

School of Continuing and Professional

Studies - CUHK

|

Roof Floor

|

1 m from facade

|

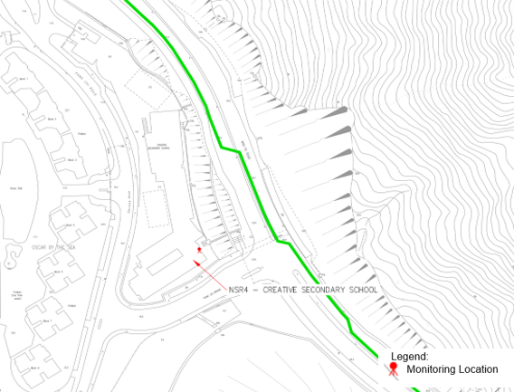

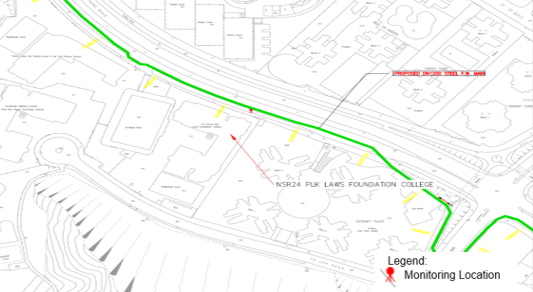

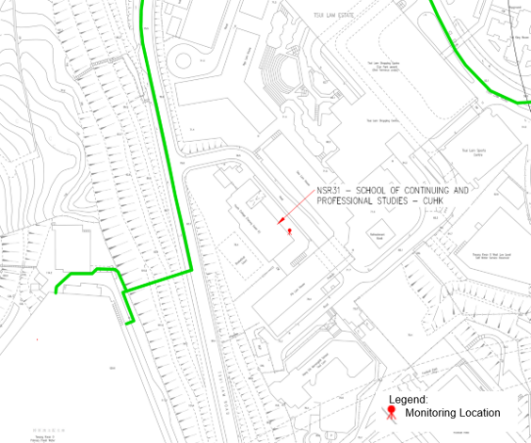

Three noise monitoring locations for impact

monitoring at the nearby sensitive receivers are shown in Figure 2.1-2.3.

|

|

Figure

2.1 NSR4 Creative Secondary School

|

|

|

Figure

2.2 NSR24 PLK Laws Foundation College

|

|

|

Figure

2.3 NSR31 School of Continuing and

Professional Studies - CUHK

|

2.4

Impact

Monitoring Methodology

Integrated sound level meters were used for

the noise monitoring. The meters were in compliance with the International

Electrotechnical Commission Publications 651: 1979 (Type 1) and 804: 1985 (Type

1) specifications. Immediately prior to and following each noise measurement

the accuracy of the sound level meters was checked using an acoustic calibrator

generating a known sound pressure level at a known frequency. Measurements may

be accepted as valid only if the calibration level before and after the noise

measurements agree to within 1.0 dB(A).

Calibration

certificates of the instruments used are presented in Appendix E. Noise

measurements were not made in the presence of fog, rain, wind with a steady

speed exceeding 5 m/s or wind with gusts exceeding 10 m/s. The wind speed was

checked with a portable wind speed meter capable of measuring the wind speed in

m/s.

Table 2.3 Impact Noise Monitoring Equipment

|

Equipment

|

Brand and Model

|

Serial Number

|

Date of Calibration

|

Expiry Date

|

|

Sound Level Meter

|

Svantek 971

|

96062

|

27/06/2022

|

26/06/2023

|

|

Sound Level Meter Calibrator

|

RION NC-75

|

34524163

|

09/05/2022

|

08/05/2023

|

|

Pocket Wind Meter Anemometer

|

Kestrel 1000 Wind Meter

|

Nil

|

Nil

|

Nil

|

2.5

Action

and Limit Levels

The Action/Limit Levels are in line with

the criteria of Practice Note for Professional Persons (ProPECC PN 2/93) “Noise

from Construction Activities – Non-statutory Controls” and Technical Memorandum

on Environmental Impact Assessment Process issued by HKSAR Environmental

Protection Department [“EPD”] under the Environmental Impact Assessment

Ordinance, Cap 499, S.16 are presented in Table 2.4.

Table 2.4 Action and Limit Levels

for Noise

|

Time Period

|

Action Level

|

Limit Level (dB(A))

|

|

0700-1900 on normal weekdays

|

When

one documented complaint is received from any one of the noise sensitive receivers

|

·

70 dB(A)

for school and

·

65 dB(A)

during examination period

|

|

Notes:

(a)

Limits

specified in the GW-TM and IND-TM for construction and operation noise,

respectively.

|

If exceedances are found during

noise monitoring, the actions in accordance with the Event and Action Plan will

be carried out according to Appendix F.

2.6

Monitoring

Results and Observations

Referring to EM&A Manual Section 4.1.2,

impact monitoring for noise impact was scheduled weekly in the reporting month

for NSR4 – Creative Secondary School on 1, 7, 13, 24 and 30 March 2023. Detailed

monitoring results are presented in Appendix G.

No construction works were conducted within

300m radius of NSR24 and NSR31. Thus, no construction noise monitoring works was

carried at these two locations in the reporting month.

No

action or limit level exceedance was recorded for construction noise monitoring

during the reporting period.

3

The

waste generated from this Project includes inert construction and demolition

(C&D) materials, and non-inert C&D materials. Non-inert C&D

materials are made up of general refuse, vegetative wastes, and recyclable

wastes such as plastics and paper/cardboard packaging waste. Steel materials

generated from the project are also grouped into non-inert C&D materials as

these materials were not disposed of with other inert C&D materials. With

reference to relevant handling records and trip tickets of this Project, the

quantities of different types of waste generated in the reporting month are

summarised in Table 3.1. Details of cumulative waste management data are

presented as a waste flow table in Appendix H.

Table 3.1 Quantities of waste generated

from the Project

|

Reporting period

|

Quantity

|

|

Inert C&D Materials

(in ‘000m3)

|

Chemical Waste

(in ‘000kg)

|

Non-inert C&D

Materials

|

|

Others, e.g., General

Refuse disposed at Landfill

(in ‘000m3)

|

Recycled materials

|

|

Paper/cardboard

(in ‘000kg)

|

Plastics

(in ‘000kg)

|

Metals

(in ‘000kg)

|

|

Mar 2023

|

1.093

|

0.000

|

0.005

|

0.059

|

0.000

|

0.000

|

4

4.1

Monitoring

Requirement

In accordance with Section 11 of

the EM&A Manual, monitoring of landfill gas is required for construction

works within the 250m Consultation Zone. Part of the desalination plant and the

indicative area of natural slope mitigation works fall within the SENT Landfill

Extension Consultation Zone; and part of the 1,200 mm diameter fresh water

mains along Wan Po Road falls within the SENT Landfill and SENT Landfill

Extension Consultation Zones, TKO Stage II/III Restored Landfill and TKO Stage

I Restored Landfill Consultation Zones.

4.2

Monitoring

Location

Monitoring of oxygen, methane, carbon

dioxide and barometric pressure was performed for excavations at 1m depth or

more within the Consultation Zone.

During

construction of works within the consultation zones, excavations of 1m depth or

more was monitored:

·

At the

ground surface before excavation commences;

·

Immediately

before any worker enters the excavation;

·

At the

beginning of each working day for the entire period when the excavation remains

open; and

·

Periodically

through the working day whilst workers are in the excavation.

For

excavations between 300mm and 1m deep, measurements should be carried out:

·

Directly

after the excavation has been completed; and

·

Periodically

whilst the excavation remains open.

The

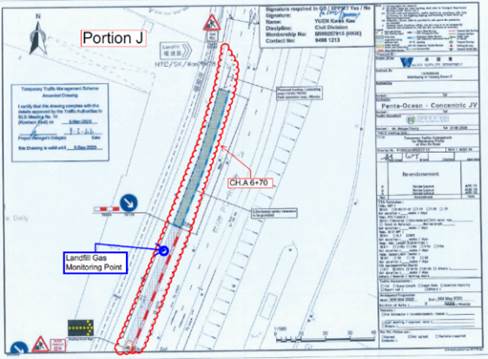

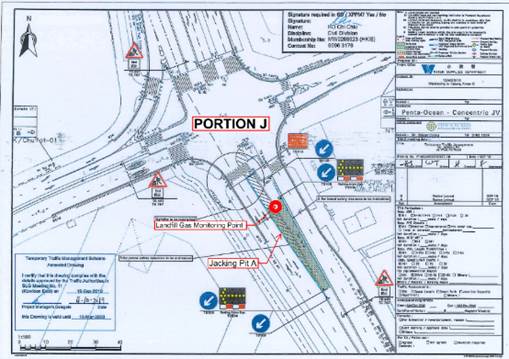

area required to be monitored for landfill gas in the reporting period are

shown in Figure 4.1 to Figure 4.9.

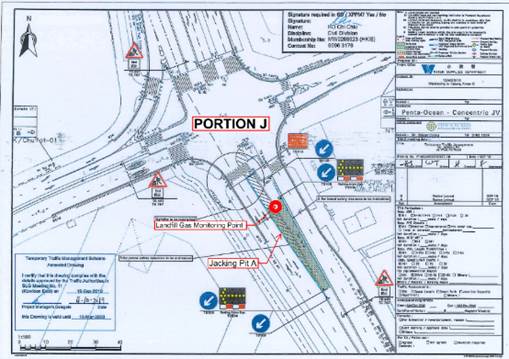

|

|

Figure

4.1 Monitoring Location - CH.A 6+70

|

|

|

|

Figure

4.2 Monitoring Location – CH.A 13+50 ~ 14+00

(Pit A)

|

|

|

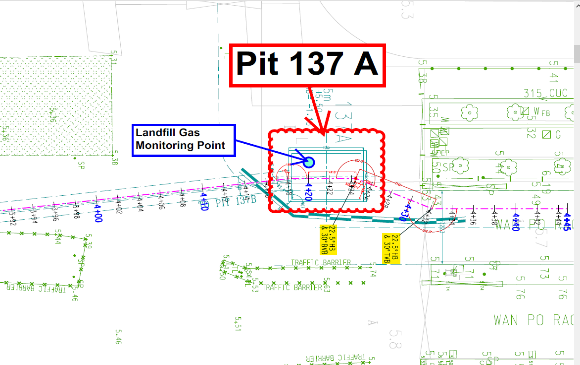

|

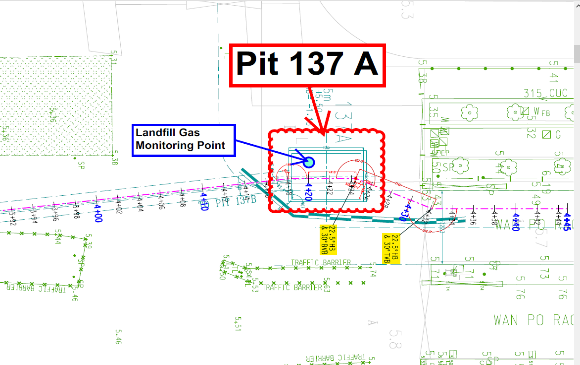

Figure

4.4 Monitoring Location – Pit 137A (137 Pit

A)

|

|

.

|

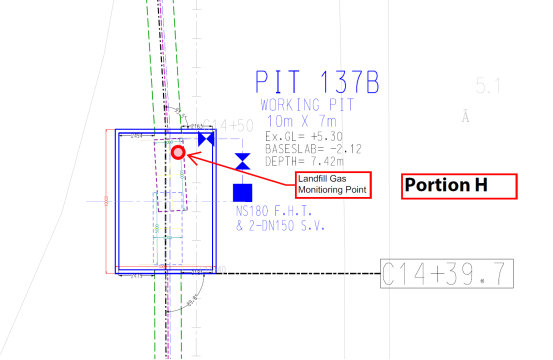

|

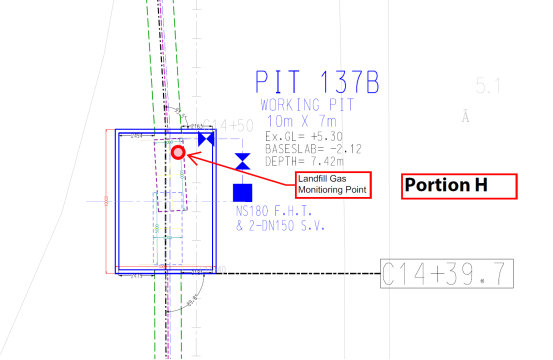

Figure

4.5 Monitoring Location – Pit 137B (137 Pit

B)

|

|

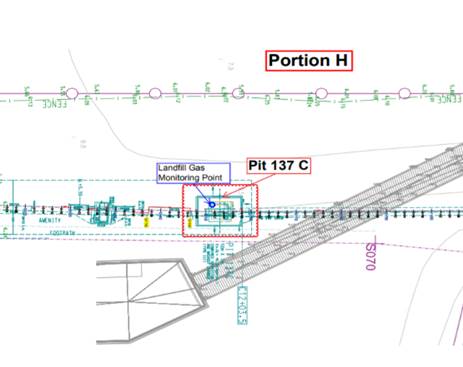

|

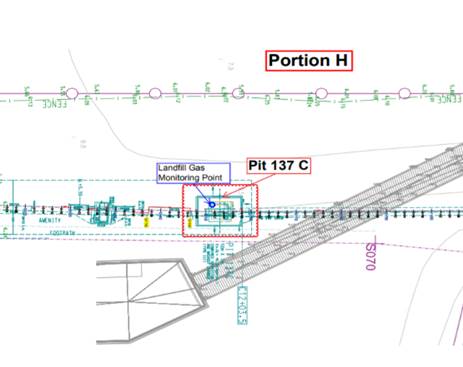

|

Figure

4.6 Monitoring Location – Pit 137C (137 Pit

C)

|

|

|

|

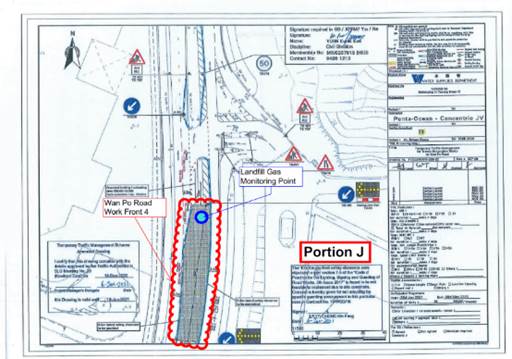

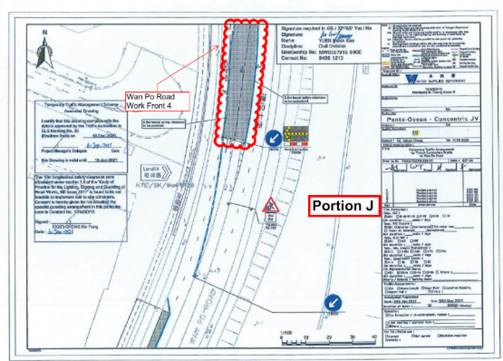

Figure

4.7 Monitoring Location – Wan Po Road 4

|

|

|

|

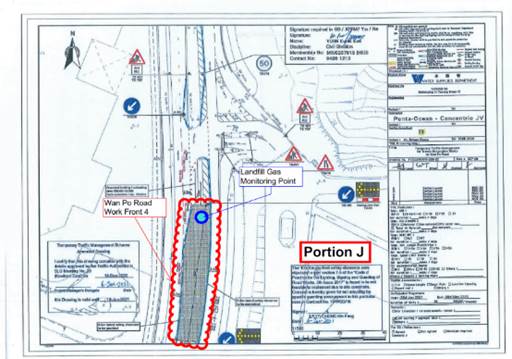

Figure

4.8 Monitoring Location – Wan Po Road 5

|

|

|

|

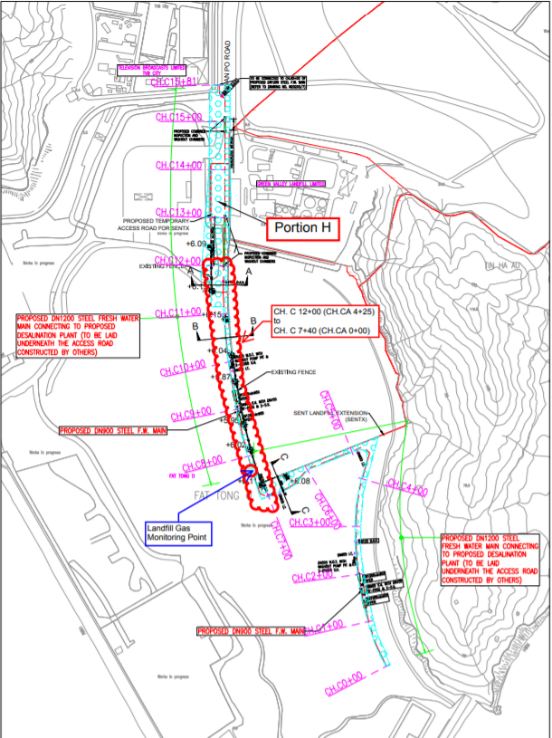

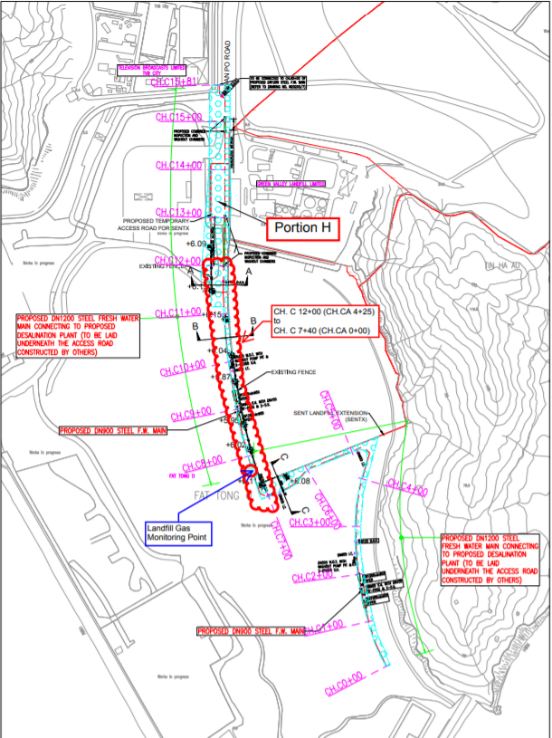

Figure

4.9 Monitoring Location –CH.CA

0+00 to CH.CA 04+25

(CH.C 7+40 ~ 12+00)

|

4.3

Monitoring

Parameters

Landfill

Gas monitoring was carried out to identify any migration between the landfill

and the Project and to ensure the safety of the construction, operation and

maintenance personnel working on-site, visitors and any other person within the

Project area.

The

following parameters were monitored:

·

Methane.

·

Oxygen.

·

Carbon

Dioxide.

·

Barometric

Pressure.

4.4

Action

and Limit Level

Action and Limit Level are provided in Table

4.1.

Table

4.1 Action and Limit Level for Landfill Gas Monitoring Equipment

|

Parameters

|

Action Level

|

Limit Level

|

|

Oxygen (O2)

|

<19% O2

|

<19% O2

|

|

Methane (CH4)

|

>10% LEL

|

>20% LEL

|

|

Carbon Dioxide (CO2)

|

>0.5% CO2

|

>1.5% CO2

|

4.5

Monitoring

Equipment

Landfill Gas monitoring was carried out

using intrinsically safe, portable multi-gas monitoring instruments. The

gas monitoring equipment is:

·

Complying

with the Landfill Gas Hazard Assessment Guidance Note as intrinsically safe;

·

Capable of

continuous barometric pressure and gas pressure measurements;

·

Normally

operated in diffusion mode unless required for spot sampling, when it should be

capable of operating by means of an aspirator or pump;

·

Having low

battery, fault and over range indication incorporated;

·

Capable of

storing monitoring data, and shall be capable of being down-loaded directly;

·

Measure in

the following ranges:

|

methane

|

0-100% Lower Explosion Limit (LEL) and 0-100%

v/v;

|

|

oxygen

|

0-25% v/v;

|

|

carbon dioxide

|

0-5% v/v; and

|

|

barometric pressure

|

mBar (absolute)

|

alarm (both

audibly and visually) in the event that the concentrations of the following are

exceeded:

|

methane

|

>10% LEL;

|

|

oxygen

|

<19% by volume; and

|

|

carbon dioxide

|

>0.5% by volume

|

|

barometric pressure

|

mBar (absolute)

|

Monitoring

Equipment used in the reporting period are summarised in Table 4.2. The Landfill Gas monitoring

equipment calibration certificate is presented in Appendix I.

Table 4.2 Landfill Gas Monitoring

Equipment

|

Equipment

|

Brand and Model

|

Calibration Expiry Date

|

|

Portable Gas Detector

|

PGM-2500 QRAE III

|

27 July 2023

|

|

XT-XWHM-Y-OR

|

2 September 2023

|

|

CO2 Analyzer

|

TES, 1307H

|

16 November 2023

|

4.6

Monitoring

Results

In the reporting period, construction works

within the consultation zones, excavations of 1m depth or more was monitored. Landfill

gas monitoring was carried out by the Registered Safety Officer of the

Contractor at the excavation locations for 564 times.

All the measured results were presented in Appendix J and were within

the Action and Limit Levels.

Table 4.3 Action and Limit Levels

and Event and Action Plan for LFG Hazard

|

Parameters

|

Level

|

Action

|

|

Oxygen (O2)

|

Action Level < 19% O2

|

Ventilate trench/void to restore O2 to

> 19%

|

|

Limit Level < 19% O2

|

Stop works

Evacuate personnel/prohibit entry

Increase ventilation to restore O2 to

> 19%

|

|

Methane

(CH4)

|

Action

Level >10% LEL

|

Post "No Smoking"

signs

Prohibit hot works

Increase ventilation to

restore CH4 to <10% LEL

|

|

Limit

Level >20% LEL

|

Stop works

Evacuate personnel/prohibit

entry

Increase ventilation to

restore CH4 to<10% LEL

|

|

Carbon

Dioxide (CO2)

|

Action

Level >0.5% CO2

|

Ventilate

to restore CO2 to < 0.5%

|

|

Limit

Level >1.5% CO2

|

Stop works

Evacuate personnel / prohibit

entry

Increase ventilation to

restore CO2 to <0.5%

|

5

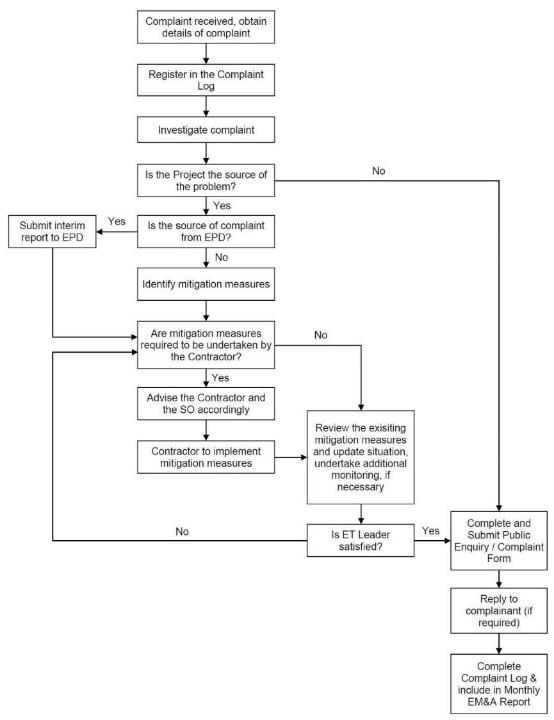

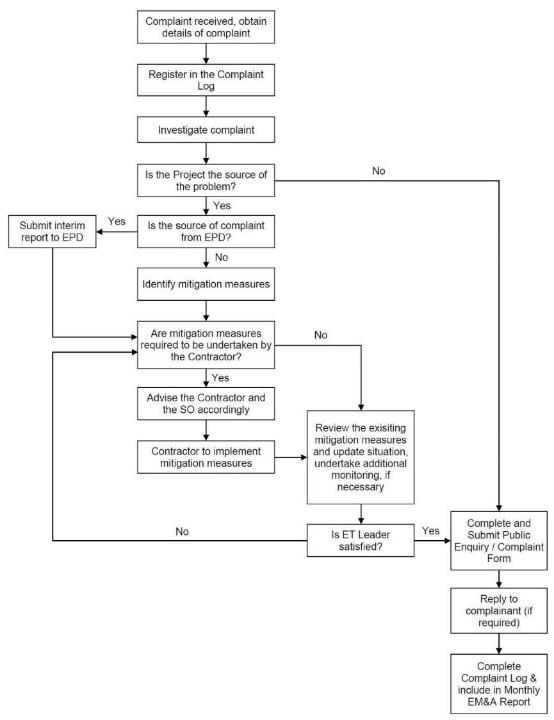

The

Environmental Complaint Handling Procedure is shown in below Figure 5.1:

Figure 5.1

Environmental Complaint Handling Procedure

Impact monitoring for noise impact was scheduled

in the reporting month for NSR4 – Creative Secondary School on 1, 7, 13, 24 and

30 March 2023 as construction works were conducted within 300m to the noise

sensitive receiver. Detailed monitoring results can be found in Appendix G.

No action or limit levels exceedance was recorded in the reporting period.

Landfill

gas monitoring was carried out by the Registered Safety Officer of the

Contractor at the excavation locations and within the consultation zones for 564

times. All the measured results were presented in Appendix J and were

within the Action and Limit Levels.

No environmental complaint,

notification of summons and prosecution was received in the reporting period.

Statistics on complaints and regulatory

compliance are summarized in Appendix K.

Site

inspections were carried out on a weekly basis to monitor the implementation of

proper environmental pollution control and mitigation measures under the

Contract. In the reporting period, site inspections were carried out on 1, 8, 14,

24 and 28 March 2023 at the site portions list in Table 6.1 below. One joint site inspections with IEC was carried

out on 28 March 2023.

Table 6.1 Site Inspection

Record

|

Date

|

Inspected Site Portion

|

Time

|

|

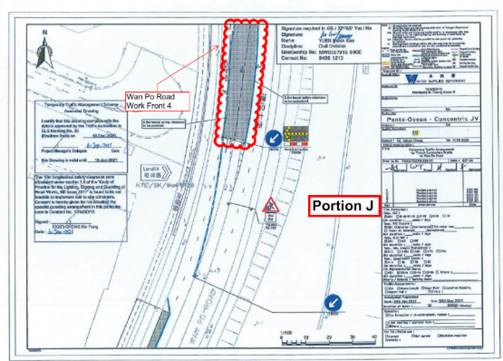

1 March 2023

|

Portion J

|

09:30 - 10:30

|

|

8 March 2023

|

Portion J

|

09:30 - 1030

|

|

14 March 2023

|

Portion J

|

09:30 - 10:30

|

|

24 March 2023

|

Portion J

|

09:30 - 10:30

|

|

28 March 2023

|

Portion J

|

14:30 – 15:30

|

Minor deficiencies were observed

during weekly site inspections. Key observations during the site inspections

are summarized in Table 6.2.

Table 6.2 Site Observations

|

Date

|

Environmental

Observations

|

Follow-up

Status

|

|

1 March 2023

|

1. Chemical container shall be

stored with drip tray.

|

1. Chemical container was stored

with drip tray.

|

|

8 March 2023

|

1. Chemical container shall be

stored with drip tray.

2. Seepage water should be

treated properly to comply with the requirement of discharge license before

discharge. (Pit O)

3. Stockpile of dusty materials

should be covered with impervious materials to prevent dust emission. (Pit O)

4. Oil leakage from the excavator

was observed at Pit O1. The Contractor was reminded to clear the oil stain to

avoid further leakage from the excavator.

|

1. Chemical containers were

stored with drip tray.

2. The watering pumping was

stopped.

3. The dusty materials were

removed.

4. The oil stain was cleared.

|

|

14

March 2023

|

1. Chemical containers should be

stored with drip tray. (WF2)

2. Oil leakage from excavator was

observed. The Contractor was required to clean the oil stain on ground. (WF2)

|

1. Chemical was removed.

2. The excavator was repaired, no

oil leakage was observed. Oil stain on ground was cleared.

|

|

24 March 2023

|

1. The sediment tank shall be

cleaned up asap. (Pit P1)

2. The blockage of the storm

drain should be cleaned up. (Pit Y)

3. The chemical containers shall

be stored on a drip tray with chemical label. (Pit P and O1)

4. The underground water shall be

discharged through sedimentation tank. (Pit P)

|

1. The sediment tank was cleaned.

2. The blockage of the storm

drain was cleaned up.

3. The chemical containers were

removed.

4.

This water

pumping is for circulation and will not be discharged into storm drain.

|

|

28 March 2023

|

1. Water pumped out from trench

should be treated before discharge. (Shek Kok Road Roundabout)

|

1.

Water pumped

out from trench was stopped.

|

According to the EIA Study

Report, Environmental Permit, contract documents and EM&A Manual, the

mitigation measures detailed in the documents should be implemented as much as

practical during the reporting period. An updated Implementation Status of

Environmental Mitigation Measures (EMIS) is provided in Appendix C.

Site inspection proforma of the reporting

period is provided in Appendix L.

Table 7.1. Key works for the

next reporting month

|

Location

|

Construction activities to be

carried out in next reporting month

|

|

Wan Po Road and TKO Area 137

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

|

|

TKO Promenade (Stage 1 Landfill) & Po

Yap Road Roundabout

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

·

Trenchless

Method (sleeve pipe)

|

|

HK Velodrome

|

·

Open trench

method

·

Water main

installation inside sleeve pipe

·

Trenchless

Method (sleeve pipe)

|

|

Po Lam Road South / Ling Hong Road

|

·

Open

trench method

·

Water main

installation inside sleeve pipe

|

|

Tsui Lam Road / Abandoned Road

|

· Open trench method

|

The major environmental impacts brought by

the above construction works will include:

·

Construction

dust and noise generation of mainlaying of pipes, TBM break through, and

excavation works;

·

Waste

generation from construction activities; and

·

Impact on

water quality from construction activities.

The key environmental mitigation

measures for the Project in the coming reporting period associated with the

above construction works will include:

·

Dust

suppression by regular wetting and water spraying for excavation works, mainlaying

of pipes and TBM break through works;

·

Reduction of

noise from equipment and machinery on-site;

·

Sorting and

storage of general refuse and construction waste; and

·

Treatment of

wastewater with water treatment facilities before discharge.

The proactive environmental

protection proforma for the next reporting month is listed in Appendix M.

Referring to EM&A Manual

Section 4.1.2, the impact noise monitoring should be carried out at all the

designated monitoring stations when there are project-related construction

activities undertaken within a radius of 300m from the monitoring stations.

The tentative impact monitoring schedule

for the next reporting month is attached in Appendix N.

This is the 56th monthly

Environmental Monitoring and Audit (EM&A) Report presenting the EM&A

works undertaken during the period from 1 March to 31 March 2023 in accordance

with the EM&A Manual and the requirement under EP-503/2015/A.

Impact

monitoring for noise impact was scheduled in the reporting month for NSR4 –

Creative Secondary School on 1, 7, 13, 24 and 30 March 2023 as construction

works were conducted within 300m to the noise sensitive received. No action and

limit level exceedance for construction noise monitoring was recorded in the

reporting period.

Landfill gas monitoring was carried out by

the Registered Safety Officer of the Contractor at the excavation locations and

within the consultation zones for 564 times. All the measured results were

presented in Appendix J and were within the Action and Limit Levels.

No exceedance of the action and limit level

for landfill gas monitoring was recorded during the reporting period.

Weekly

environmental site inspections were conducted during the reporting month. Observations

and Recommendation were made during site inspection, Contractor was reminded

that sedimentation facilities shall be provided on site to remove silt

particles from runoff before discharge and to meet the requirements of the TM standard

under the WPCO.

According to the environmental

site inspections performed in the reporting month, the contractor is reminded

to pay attention on maintaining site tidiness, water treatment facilities, and

proper materials storage.

No

environmental complaint, notification of summons and prosecution was received in the reporting month.

The

ET will keep track on the construction works to confirm compliance of

environmental requirements and the proper implementation of all necessary

mitigation measures.